Thermochemical CO2 Utilization

Our thermochemical research seeks to establish the chemical basis for processes that convert CO2 into high-volume products. To be viable, these processes must minimize energy intensity, avoid consuming stoichiometric reagents, and produce no waste. Ideally, they would also afford a distinct chemical advantage or process intensification relative to a conventional route. Our strategy is inspired by the simplicity of the natural Calvin-Benson cycle in nature, which uses acid-base chemistry (C–H deprotonation) to generate a reactive intermediate that engages CO2 in C–C bond formation. We seek to generalize this strategy by developing ways to use carbonate (CO32–) to promote C–H carboxylation reactions, which can be incorporated into closed cycles (no waste generation) for synthesizing carboxylic acids. Building on these studies, we are also developing catalysts that use acid-base chemistry to catalyze CO2 hydrogenation, providing a way to convert the chemical energy of H2 into carbon-containing fuels.

C–H bonds are very weak acids and cannot be deprotonated by a weak base such as CO32– in conventional reaction media. We have found that solvent-free systems composed of alkali salts enable CO32– to reversibly deprotonate very weakly acidic C–H bonds at intermediate temperatures, generating carbanions that readily trap CO2 to form carboxylates (C–CO2–). We have used this reaction to develop a novel process for synthesizing furan-2,5-dicarboxylic acid (FDCA), a monomer that is used to make performance-advantaged polyester plastic. Our carboxylation route sources FDCA from CO2 and inedible biomass and eliminates much of the complexity of competing processes that make FDCA from fructose. We have also applied carbonate-promoted C–H carboxylation to generate polyamide monomers from furfurylamine, a feedstock prepared in one step from furfural. These application-focused projects have led to fundamental studies to investigate the phase behavior of solvent-free systems and explore their utility for other bond-forming reactions.

We are also developing ways to perform C–H carboxylation as a gas–solid reaction with substrates that can be volatilized. We have found that dispersing alkali carbonates (M2CO3) in mesoporous materials disrupts the crystalline lattice, resulting in amorphous surface carbonates that are capable of deprotonating un-activated C–H bonds at elevated temperature in the presence of CO2. We have demonstrated that these materials can be used to perform C–H carboxylation of aromatic hydrocarbons such as benzene and naphthalene. Ongoing efforts seek to discern the local structure of these amorphous carbonates, develop strategies to further enhance their basicity, and broaden the substrate scope.

Electrochemical C2+ Synthesis

The overarching goal of our electrochemistry research is to enable an energy- and carbon-efficient electrosynthesis of valuable multi-carbon (C2+) chemicals. Our efforts range from fundamental studies to device engineering. A longstanding topic of interest in the group is the relationship between bulk defects in materials and their electrocatalytic activity. Our work has shown that the activity for CO2 reduction to CO on Au and CO reduction to C2 oxygenates (ethanol, acetate) on Cu is correlated to the density of grain boundaries in these materials. Using spatially resolved electrochemical measurements in combination with grain mapping techniques, we have found that grain boundary surface terminations selectively enhance CO2 electroreduction but not the competing H2O reduction on Au, supporting a model in which grain boundaries give rise to metastable surface structures with favorable catalytic properties. Ongoing work aims to quantify the relationship between activity, defect-density, and strain for CO2 and CO reduction on Au and Cu and translate these findings into catalyst design principles. In support of these goals, we also work to improve techniques for mapping grain structures and to develop new strategies for studying the structural evolution of defects under electrochemical conditions. All of these efforts involve multiple collaborations with other research groups and national laboratories.

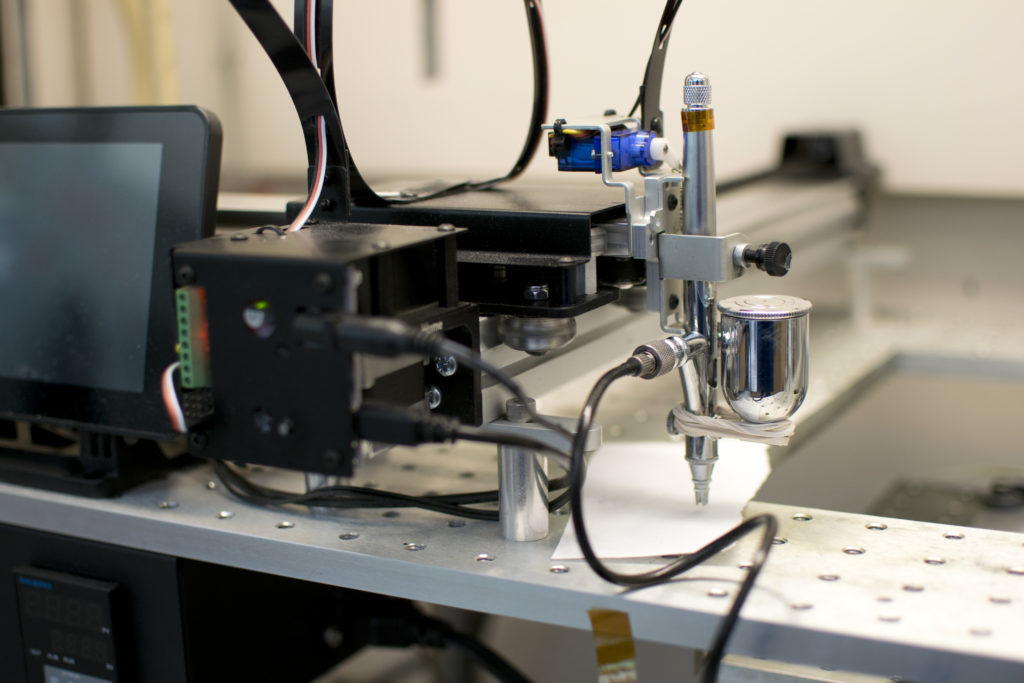

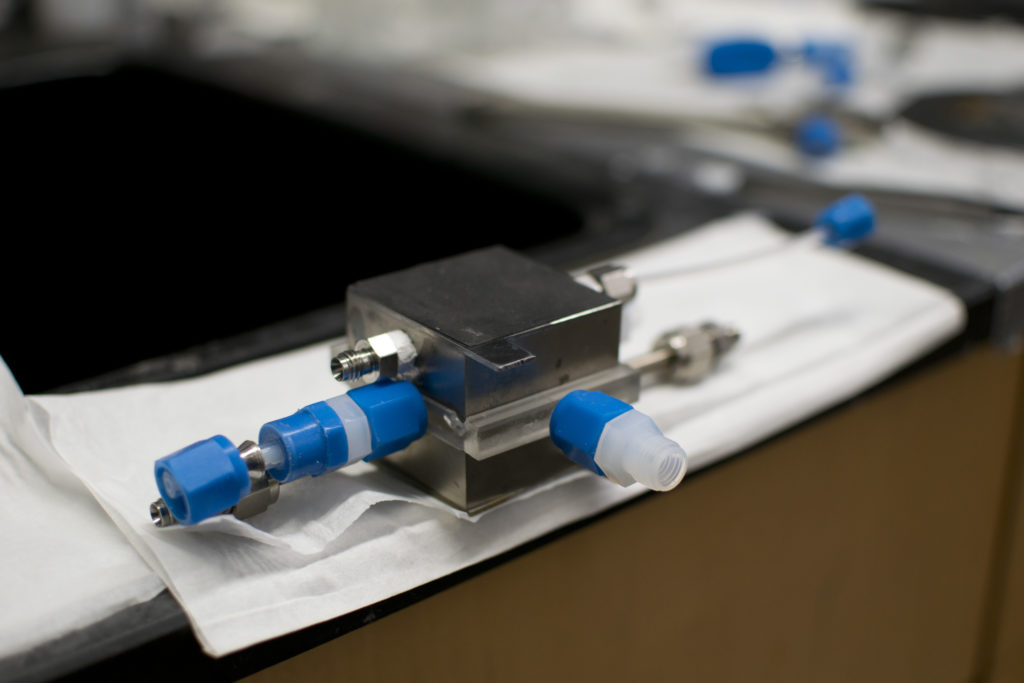

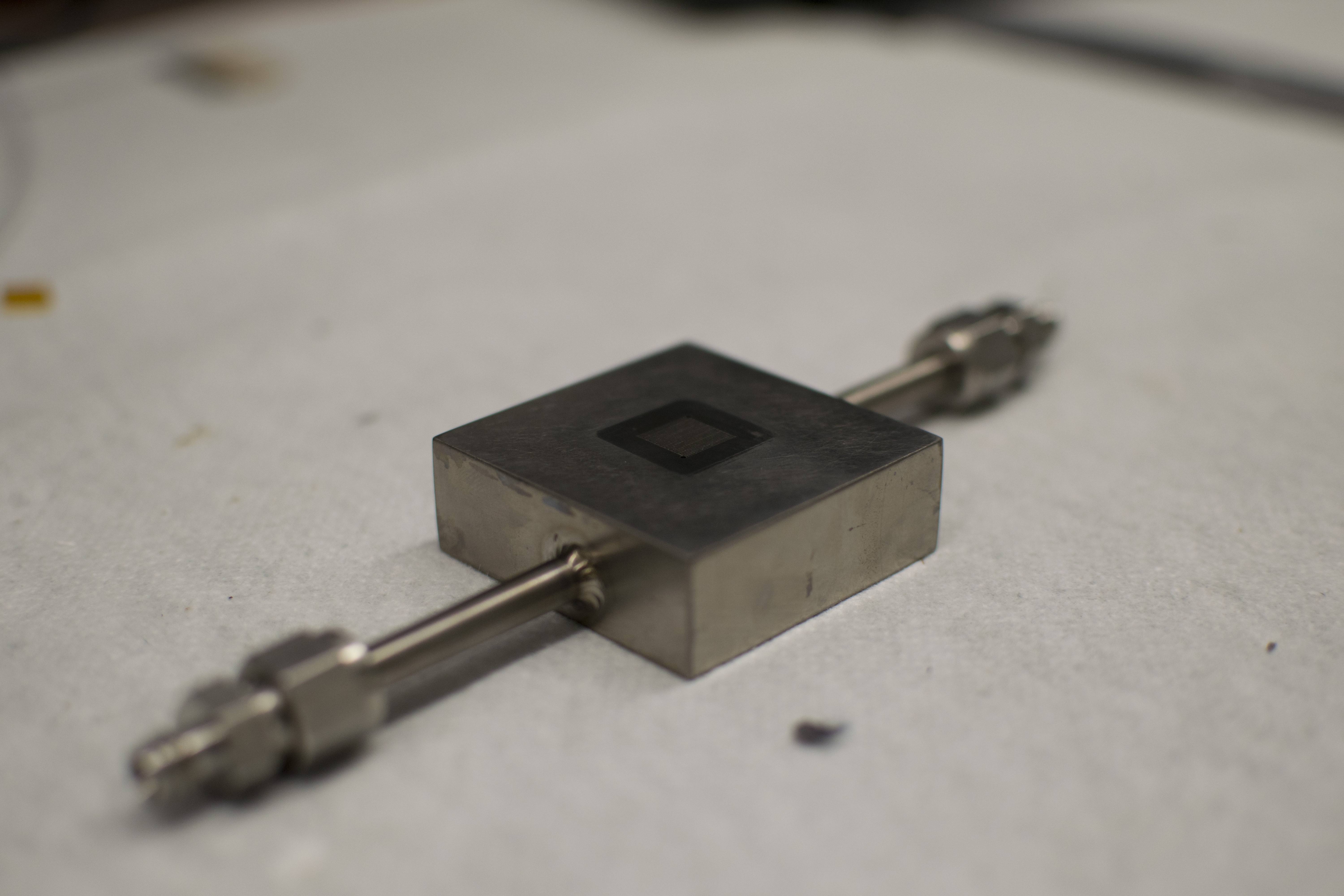

Our research in devices is focused on the development of gas diffusion CO electrolysis cells to synthesize products including ethylene, acetate, ethanol and propanol. We envision that these devices would be coupled with an upstream CO2-to-CO electrolyzer to achieve an overall 2-step conversion of CO2 into C2+ targets. Our work includes designing and evaluating novel cell architectures to improve the energy- and atom-efficiency of CO electrolysis. We have recently demonstrated cells that achieve synthetically relevant current densities at high single-pass CO conversions, enabling the direct production of concentrated product streams. We are developing computational models to identify and alleviate transport barriers and using 3D printing to rapidly iterate prototypes. In addition to optimizing performance through cell design, we are investigating ways to improve the activity and durability of the cathode (where CO reduction occurs) by changing the structure and formulation of the catalyst layer. Ultimately, we aim to translate our structure–activity research to catalysts operating in real devices with optimized transport properties.